One of our employees who owns a 2010 Cobalt Turbo was working on his car the other day and noticed something interesting when his intake manifold was off of his cylinder head.

He noticed that there was a lot of varnishing of the valves compared to a typical gas engine where the injectors are inside the intake manifold.

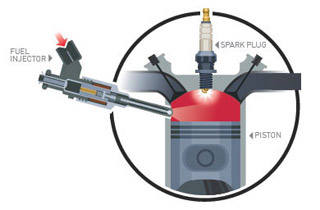

First off, for those of you who arent familiar with direct injection, its a new technology that more and more manufacturers are phasing into engine design. Instead of the fuel injector being put in the intake manifold, its placed below the valves and directly inside the combustion chamber. By doing this, fuel is more efficiently sprayed into the combustion chamber, providing better gas mileage, and power. Most manufacturers have seen improvements in gas mileage and power by as much as 15%.

It works well, however there is one minor downside to direct injection in our observation and its that the fuel that would normally clean the runners before the chamber, and the valves are not cleaned by the fuel traveling towards the chamber. This means direct injection motors will have more varnish as seen in our employees engine:

These photos were taken when this motor had 9,000 miles.

Direct injection injector

Diagram of side profile of a direct injection system

Now, the same varnishing and carbon buildup happens in regular gas motors as well, so we’re not saying the direct injection motor is not a flawed design, it just has more carbon buildup compared.